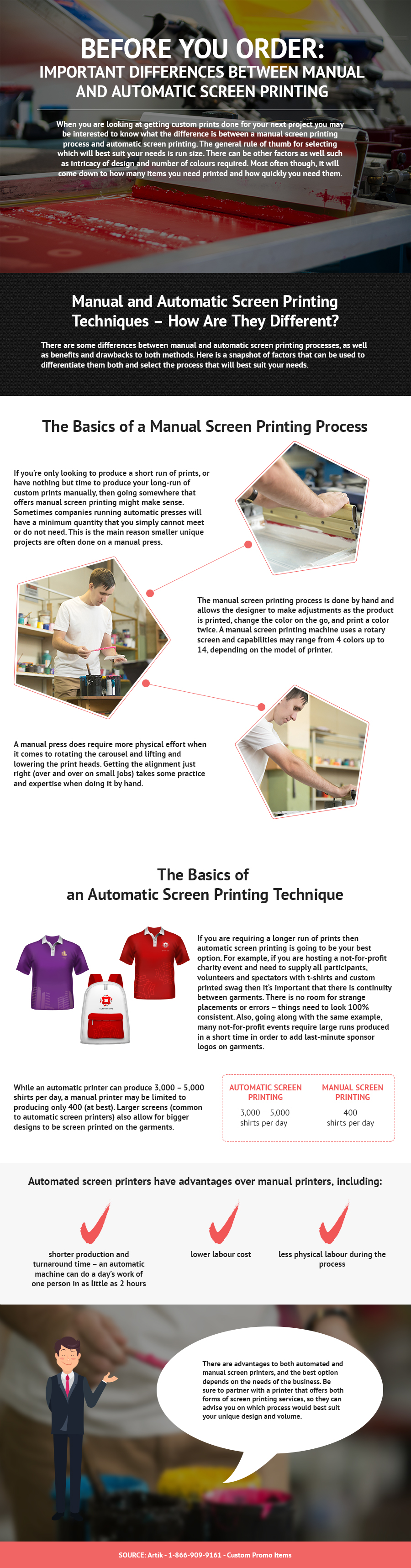

When you are looking at getting custom prints done for your next project you may be interested to know what the difference is between a manual screen printing process and automatic screen printing. The general rule of thumb for selecting which will best suit your needs is run size. There can be other factors as well such as intricacy of design and number of colours required. Most often though, it will come down to how many items you need printed and how quickly you need them.

Manual and Automatic Screen Printing Techniques – How Are They Different?

There are some differences between manual and automatic screen printing processes, as well as benefits and drawbacks to both methods. Here is a snapshot of factors that can be used to differentiate them both and select the process that will best suit your needs.

The Basics of a Manual Screen Printing Process

If you’re only looking to produce a short run of prints, or have nothing but time to produce your long-run of custom prints manually, then going somewhere that offers manual screen printing might make sense. Sometimes companies running automatic presses will have a minimum quantity that you simply cannot meet or do not need. This is the main reason smaller unique projects are often done on a manual press.

The manual screen printing process is done by hand and allows the designer to make adjustments as the product is printed, change the color on the go, and print a color twice. A manual screen printing machine uses a rotary screen and capabilities may range from 4 colors up to 14, depending on the model of printer.

A manual press does require more physical effort when it comes to rotating the carousel and lifting and lowering the print heads. Getting the alignment just right (over and over on small jobs) takes some practice and expertise when doing it by hand.

The Basics of an Automatic Screen Printing Technique

If you are requiring a longer run of prints then automatic screen printing is going to be your best option. For example, if you are hosting a not-for-profit charity event and need to supply all participants, volunteers and spectators with t-shirts and custom printed swag then it’s important that there is continuity between garments. There is no room for strange placements or errors – things need to look 100% consistent. Also, going along with the same example, many not-for-profit events require large runs produced in a short time in order to add last-minute sponsor logos on garments.

While an automatic printer can produce 3,000 – 5,000 shirts per day, a manual printer may be limited to producing only 400 (at best). Larger screens (common to automatic screen printers) also allow for bigger designs to be screen printed on the garments.

Automated screen printers have advantages over manual printers, including:

- shorter production and turnaround time – an automatic machine can do a day’s work of one person in as little as 2 hours

- lower labour cost

- less physical labour during the process

There are advantages to both automated and manual screen printers, and the best option depends on the needs of the business. Be sure to partner with a printer that offers both forms of screen printing services, so they can advise you on which process would best suit your unique design and volume.

Contact us today to discuss your screen printing project.